| Historical Information

Formed in 1901 as an

amalgamation of Carnegie Steel, Federal Steel and a number of other

small companies, the alumni of the Pittsburgh based US Steel

Corporation were a veritable “Who’s Who” of American

Industry. Created by J. P. Morgan, Elbert H and Andrew

Carnegie, with Charles M. Schwab serving as its first President, within

four years of its founding, the company was experiencing meteoric

growth, with its eye on dramatically expanding its operations.

With a need to locate close to

a harbor to receive ore, coal and limestone, to rail lines to ship

finished product, and to a population center which could fill the

numerous jobs the new mills would create, it quickly became evident

that the area around Chicago provided the key to the company’s growth

potential. However, water front property in the Chicago area was

virtually nonexistent and prohibitively expensive in those rare cases

in which it became available. Taking a cue from competitor Inland

Steel, which had previously purchased unimproved lakeshore to build its

base of operations at Indiana Harbor, US Steel Chairman Elbert H. Gary

set his sights on the sprawling Indiana dunes two miles to the east of

Indiana Harbor as a potential site at which to base its expansion. With a need to locate close to

a harbor to receive ore, coal and limestone, to rail lines to ship

finished product, and to a population center which could fill the

numerous jobs the new mills would create, it quickly became evident

that the area around Chicago provided the key to the company’s growth

potential. However, water front property in the Chicago area was

virtually nonexistent and prohibitively expensive in those rare cases

in which it became available. Taking a cue from competitor Inland

Steel, which had previously purchased unimproved lakeshore to build its

base of operations at Indiana Harbor, US Steel Chairman Elbert H. Gary

set his sights on the sprawling Indiana dunes two miles to the east of

Indiana Harbor as a potential site at which to base its expansion.

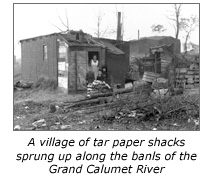

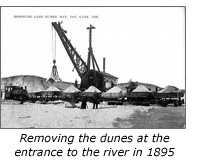

After consummating the

necessary land purchases in 1905, U. S. Steel formed a subsidiary by

the name of Indiana Steel which would be charged with building and

operating the new plant. As a result of the completely unimproved

nature of the dunes, the formidable task of leveling and preparing the

land was already underway in the spring of 1906. With no local

accommodations in this virtual wilderness, a village of tar paper

shacks quickly sprang up along the shore of the Grand Calumet River to

serve as temporary housing for the thousands of workers and their

families who swept into the area to help clear the land and build the

mills and harbor. Working teams of horses and mules pulling grader

blades and wagons, the army of workers made innumerable passes along

the dunes to level the hills and valleys, removing many thousands of

tons of sand, marshland and vegetation in the process. After consummating the

necessary land purchases in 1905, U. S. Steel formed a subsidiary by

the name of Indiana Steel which would be charged with building and

operating the new plant. As a result of the completely unimproved

nature of the dunes, the formidable task of leveling and preparing the

land was already underway in the spring of 1906. With no local

accommodations in this virtual wilderness, a village of tar paper

shacks quickly sprang up along the shore of the Grand Calumet River to

serve as temporary housing for the thousands of workers and their

families who swept into the area to help clear the land and build the

mills and harbor. Working teams of horses and mules pulling grader

blades and wagons, the army of workers made innumerable passes along

the dunes to level the hills and valleys, removing many thousands of

tons of sand, marshland and vegetation in the process.

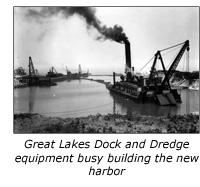

Chicago’s Great Lakes Dock and

Dredge Company was awarded the contract to build what would become

known as Gary Harbor, and while work was underway on shore, a fleet of

dredges, barges, tugs and workers, were busy excavating a huge 25-foot

deep channel some 5,000 feet long and 250 feet wide into the shoreline

to supply the planned compliment of twelve blast furnaces and

forty-seven steel furnaces. At the inner end of this huge slip, a

750-foot turning basin, large enough to allow the largest steamers of

the day to make a turn, was established. Chicago’s Great Lakes Dock and

Dredge Company was awarded the contract to build what would become

known as Gary Harbor, and while work was underway on shore, a fleet of

dredges, barges, tugs and workers, were busy excavating a huge 25-foot

deep channel some 5,000 feet long and 250 feet wide into the shoreline

to supply the planned compliment of twelve blast furnaces and

forty-seven steel furnaces. At the inner end of this huge slip, a

750-foot turning basin, large enough to allow the largest steamers of

the day to make a turn, was established.

To serve as a protection to

the channel entrance, two 2,000 foot long parallel piers were erected

at its mouth, also with a width of 250 feet between them as an

extension to the dredged channel. To serve as a range for vessels

approaching the harbor, the outer end of the west pier was lighted with

a skeletal iron tower equipped with an acetylene illuminating apparatus

at a height of 30 feet above the water, with a second similar structure

with its light located at 45 feet above the water some 200 feet to the

rear of the pierhead light to serve as the rear range.

With construction of the

harbor underway, a subsidiary of Indiana Steel known as the Gary Land

Company was formed to plan, lay out, and build both the mills and the

town of Gary. The mills and the town were built simultaneously.

Broadway Street and Fifth Avenue were designated as the two main

thoroughfares, with Broadway running from the south end of town

northward toward the main gate of the steel mill. When building the

town, workers initially laid out streets and sidewalks, and then began

construction of public and commercial structures. In a clear indication

of Gary's identity as a “company town,” the city hall and public

library were built on Broadway to the north of Fifth Avenue, and

immediately facing the main mill entrance. With construction of the

harbor underway, a subsidiary of Indiana Steel known as the Gary Land

Company was formed to plan, lay out, and build both the mills and the

town of Gary. The mills and the town were built simultaneously.

Broadway Street and Fifth Avenue were designated as the two main

thoroughfares, with Broadway running from the south end of town

northward toward the main gate of the steel mill. When building the

town, workers initially laid out streets and sidewalks, and then began

construction of public and commercial structures. In a clear indication

of Gary's identity as a “company town,” the city hall and public

library were built on Broadway to the north of Fifth Avenue, and

immediately facing the main mill entrance.

Down in the harbor, it was

soon found that vessels docked within the channel were buffeted by

northerly winds, and to further protect in such conditions, two

cross-channel piers were erected in order to create a rudimentary

stilling basin. The outer cross-channel pier extended 133 feet at a

right angle from the east pier, and the inner cross-channel pier

extended 160 feet at a right angle from the west pier approximately 790

feet inside the outer cross-channel pier. These cross channel piers

left a clear space of 90 feet between the piers for vessels to enter

and exit the channel. Minor post lights also graced the end of the west

pier and the inner ends of both cross-piers.

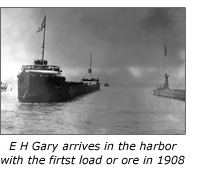

In a grand celebration

attended by company dignitaries and newspaper men from far and wide,

the US Steel owned ore boat E. H. GARY arrived with the first load of

ore from the Mesabi mines on July 23, 1908. On December 21st

of that same year, the first blast furnace was fired, and the mill was

in operation a little over two years after the first load of sand was

cleared from the dunes to make way for the complex. In a grand celebration

attended by company dignitaries and newspaper men from far and wide,

the US Steel owned ore boat E. H. GARY arrived with the first load of

ore from the Mesabi mines on July 23, 1908. On December 21st

of that same year, the first blast furnace was fired, and the mill was

in operation a little over two years after the first load of sand was

cleared from the dunes to make way for the complex.

With U.S. Steel now serving as

one of the largest companies in his district, Indiana Congressmen

Crumpacker introduced wording into the 1910 River and Harbor Bill

through which the federal government was requested to evaluate the

harbor at Gary with an eye on taking on responsibility for its future

maintenance and lighting. However, in hearings on the bill in Congress

that year, it was determined that since the harbor solely served the

interests of US Steel and its subsidiaries, it was not in the general

interest of area commerce to absorb the harbor, and unless the scheme

of development of the harbor were modified so as to permit a more

general use, the federal government was not bound to accept any

responsibility for its ongoing maintenance.

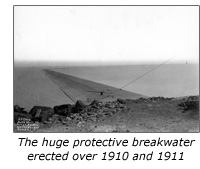

The cross piers proved to be a

less than successful solution, and without the prospect of receiving

any federal assistance in improving the harbor, over 1910 and 1911 the

company had no alternative but to build a substantial breakwater

emanating from the western side of the harbor to fully protect the

channel from northern seas. Constructed of stone-filled timber cribs,

the upper surface of the breakwater was covered in pine boards in order

to create a substantial deterrent to waves. The cross piers proved to be a

less than successful solution, and without the prospect of receiving

any federal assistance in improving the harbor, over 1910 and 1911 the

company had no alternative but to build a substantial breakwater

emanating from the western side of the harbor to fully protect the

channel from northern seas. Constructed of stone-filled timber cribs,

the upper surface of the breakwater was covered in pine boards in order

to create a substantial deterrent to waves.

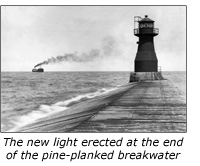

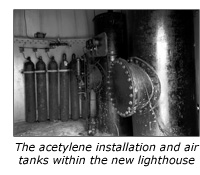

Since vessels would now need

to make a sharp turn around the end of the breakwater in order to align

themselves for entry into the channel, a new and more substantial light

was erected on a concrete base at the breakwater’s outer end. The

structure consisted of a maroon-painted, stepped cylindrical tower

capped by a  lantern with helical astragals housing a lens lantern at a

focal plane of 40 feet above the lake level. Powered by acetylene gas

from tanks stored in the base of the tower, the light output 900

candlepower and was automatically lighted at dusk and extinguished at

dawn through the use of a sun valve. As was the case with virtually all

acetylene lighting systems, the light exhibited a fast flash in order

to conserve the expensive gas. Exhibiting a repeated 15.7 second

characteristic consisting of a 2 second flash lantern with helical astragals housing a lens lantern at a

focal plane of 40 feet above the lake level. Powered by acetylene gas

from tanks stored in the base of the tower, the light output 900

candlepower and was automatically lighted at dusk and extinguished at

dawn through the use of a sun valve. As was the case with virtually all

acetylene lighting systems, the light exhibited a fast flash in order

to conserve the expensive gas. Exhibiting a repeated 15.7 second

characteristic consisting of a 2 second flash  followed by a 2.7 second

eclipse, a second 2 second flash and an eclipse of 9 seconds, the new

Gary Breakwater light was exhibited for the first time on the night of

July 5th, 1911. To help provide guidance during thick weather, the

structure was also equipped with a six-inch air operated siren which

emitted a repeated characteristic of a 2 second blast followed by 28

seconds of silence. followed by a 2.7 second

eclipse, a second 2 second flash and an eclipse of 9 seconds, the new

Gary Breakwater light was exhibited for the first time on the night of

July 5th, 1911. To help provide guidance during thick weather, the

structure was also equipped with a six-inch air operated siren which

emitted a repeated characteristic of a 2 second blast followed by 28

seconds of silence.

Under Chairman Elbert H.

Gary’s stewardship, U.S Steel continued to grow to incredible

proportions. By 1916 he was leading a corporate empire with income and

resources greater than most countries. For that year alone, the

company’s gross receipts topped $1,230,000,000, and employed over

275,000, more than the US army and navy combined. If laid

end-to-end, the company’s fleet of over 100 steamers would stretch over

ten miles, and its own railroad lines would have stretched from San

Francisco to New York and a couple hundred miles beyond.

As the years passed, U.S.

Steel's corporate mission and structure passed through a number of

changes. As demand for domestic steel dropped in the 1980s, U.S. Steel

went through a major restructuring, diversifying its holdings into the

energy and transportation sectors and ultimately adopted the name USX

Corporation. In 2001, shareholders voted to separate the steel

component of its business from USX and reestablished a new publicly

traded company under the original name, U.S. Steel Corporation. After

this reorganization, the Marathon Oil Company emerged from former USX

energy sector businesses. As the years passed, U.S.

Steel's corporate mission and structure passed through a number of

changes. As demand for domestic steel dropped in the 1980s, U.S. Steel

went through a major restructuring, diversifying its holdings into the

energy and transportation sectors and ultimately adopted the name USX

Corporation. In 2001, shareholders voted to separate the steel

component of its business from USX and reestablished a new publicly

traded company under the original name, U.S. Steel Corporation. After

this reorganization, the Marathon Oil Company emerged from former USX

energy sector businesses.

U.S. Steel continues to

maintain its headquarters in Pittsburgh, and maintains a significant

presence among worldwide steel companies. It maintains large-scale production operations in the U.S., Canada and Central Europe, as well

as joint ventures in Mexico and South America. In 2007, it was ranked

by the World Steel Association as the world’s tenth largest steel

producer. U.S. Steel continues to

maintain its headquarters in Pittsburgh, and maintains a significant

presence among worldwide steel companies. It maintains large-scale production operations in the U.S., Canada and Central Europe, as well

as joint ventures in Mexico and South America. In 2007, it was ranked

by the World Steel Association as the world’s tenth largest steel

producer.

Today,

the old 1911 Gary

Breakwater light and diaphragm horn receive their power from an

electrical conduit which runs out along the concrete breakwater from

shore. While certainly not as busy as they were when US Steel reigned

as the single largest steel producer in the world, today’s

thousand-footers still look for the Gary Harbor light as they seek to

make their turn around the breakwater and into the docks in the channel

to unload Lake Superior ore for the hungry steel mills.

Seeing this Light

Because the breakwater and

lighthouse are both on private property, and there are numerous large

buildings between any public access areas and the lighthouse, the light is virtually impossible to see from the

land. Either a private boat or a vessel chartered from a local fisherman

represent the only opportunitis to obtain a good view of this light.

Both the Great Lakes Lighthouse Keepers Association and the United

States Lighthouse Society offer infrequent tours of the suth end of

Lake Michigan, both of which have always provided great close-up views

of this and the other lighthouses of the area. GPS Coordinates: 41°37'49.17"N x 87°19'13.03"W

Reference sources

Hammond Times newspaper, February 12, 1909

Report on the River & Harbor Bill, 1910

Cleveland Plain Dealer newspaper, various

Report of Hydrographic information for Lake Michigan, 1911

Annual reports of the Lake Carriers Asssociation, various

Chicago, Its History & Builders, J Seymour Currey, 1912

Great Lakes Light Lists, various |