While

the surveyors laying out the canal right-of-way tried to find the most level land

possible, Fort Wayne was approximately 90 feet higher than Lagro. (In fact, Fort Wayne was

the highest elevation along the Canal, and thus came to be known as "The Summit

City", a nickname that endures to this day. ) In order to encompass such a change in

elevation, locks were used in order to provide a means of raising and lowering the boats

between sections of virtually flat canal. While

the surveyors laying out the canal right-of-way tried to find the most level land

possible, Fort Wayne was approximately 90 feet higher than Lagro. (In fact, Fort Wayne was

the highest elevation along the Canal, and thus came to be known as "The Summit

City", a nickname that endures to this day. ) In order to encompass such a change in

elevation, locks were used in order to provide a means of raising and lowering the boats

between sections of virtually flat canal.

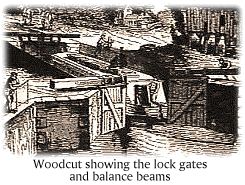

In essence, a lock is

a walled section within the canal, with water-tight doors at each end. With a boat between

the tightly closed doors, the water level within the lock could be raise or lowered to

allow the boat to move up or down stream.

The doors at each end

of the lock were massive wooden structures, with large balance beams across the top to

both balance the weight of the doors and to provide the leverage necessary to allow the

heavy doors to be opened and closed by one man. Within each door was a smaller door known

as a sluice, or wicket. The wicket could be opened or closed, allowing water to enter or

escape as required.

Due to the varying

availability of materials encountered along the path

of the canal, the locks constructed on the Wabash and Erie Canal conformed to four

different specifications: Due to the varying

availability of materials encountered along the path

of the canal, the locks constructed on the Wabash and Erie Canal conformed to four

different specifications:

Cut stone locks

The most durable and most expensive type of lock

construction, the chamber was built of stone blocks cut and fitted accurately enough to be

water- tight. Due to the lack of suitable stone, only 14 of the 73 W&E locks in

Indiana were built of stone.

Composite locks

Composite, or "combined" locks were used where

building stone of inferior quality could be obtained. Rough stone walls were lined with

planks to make a water tight chamber.

Timber Crib Locks

This was the most common type of lock construction on the

Wabash & Erie, accounting for over half of the Indiana locks. Huge boxes, or

"cribs" built log cabin style were filled with stones and gravel to form the

sides of the lock chamber and to provide the necessary stability

Timber frame locks

This was the least expensive (and least durable) of the

four types of Wabash & Erie canal locks. The sides of the chamber were braced with

heavy timber frames. These locks required frequent replacement of decayed timbers.

Profile of the Wabash & Erie Canal. Thomas Meek,

1984

No |

Lift |

Location |

Construction |

Name |

4 |

10 ft. |

Roanoke |

Timber Frame |

Dickey |

5 |

9 ft. |

Huntington |

Timber Crib |

Unknown |

6 |

8 ft. |

Huntington |

Timber Crib |

Burke |

7 |

8 ft. |

Huntington |

Composite |

Davies |

8 |

9 ft. |

Huntington |

Timber Crib |

Sunderman |

9 |

9 ft. |

Huntington |

Timber Crib |

Forks |

10 |

9 ft. |

Huntington |

Timber Crib |

Unknown |

11 |

6 ft. |

Silver Creek |

Timber Crib |

Chesboro |

12 |

8 ft. |

East of Lagro |

Cut Stone |

Jim McDonald |

13 |

7 ft. |

East of Lagro |

Cut Stone |

Curly Hayes |

14 |

6 ft. |

Lagro |

Cut Stone |

Jim Kerr |

15 |

6 ft. |

Lagro |

Cut Stone |

Jim Ditton |

|